- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

5 Advantages To Using SMT

Non-standard PCB Conveyor

August 14, 2019

PCB/LED cutting machine

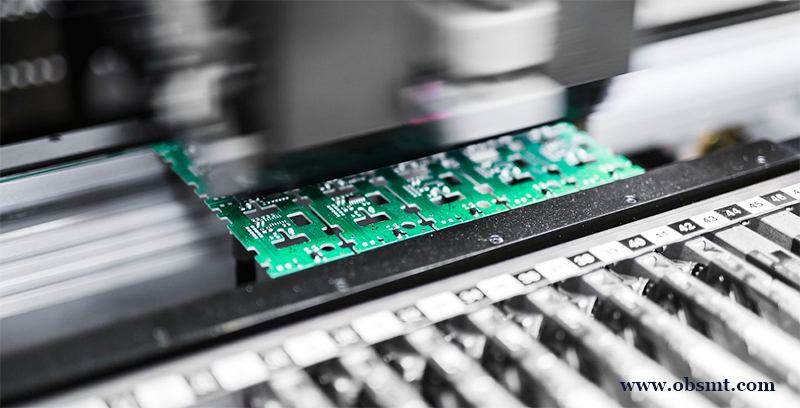

August 21, 2019The old saying “bigger is better” just isn’t accurate in the world of electronics. This is especially true when it comes to Surface-Mount Technology (SMT).

OUBEL-Surface Mount Technology

SMT places components directly onto the surface of a printed circuit board in order to create a circuit. It has become a preferred method of creating circuits in the electronics industry.

Here are some of the advantages of using SMT:

1.Small Footprint:

If you are dealing with a small PCB board, placing your components with surface-mount technology can keep the board small.

SMT components are smaller than those used in through-hole because it has either smaller leads or no leads at all. Because of this it takes up less than half of the space a through-hole mount would take. It will also lead to a decrease in weight of the PCB.

2.Low Cost:

The advantage of small size. Once set, SMT typically requires lower production costs than through-hole placement. The size of the board is reduced, the number of drilled holes is reduced, and routing of traces is reduced. So brings down the cost of the whole project.

3.Higher Density:

You are able to pack more on your PCB using SMT. Because there are no holes, you can add more components per unit of area.

You can also add more connections per component. And, because holes do not block routing space on inner or back-side layers, components can be placed on both sides of the circuit board. That can sometimes reduce the need for multi-layer boards.

OUBEL-Surface Mount Technology

4.Quick Turn Around:

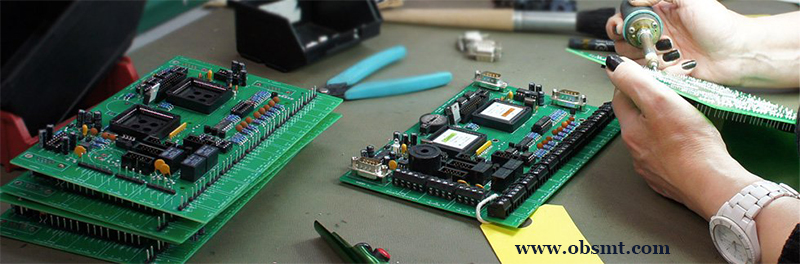

SMT is a much more streamlined manufacturing process compared to through-hole. Time is saved because components are applied using a solder paste instead of drilling holes in the PCB.

OUBEL-Surface Mount Technology

5.In-House Engineering for Testing/Prototype:

Having in-house engineering for your testing and prototyping of SMT can help during the design phase. They are able to test on the spot and/or make corrections, test new power sources, etc.

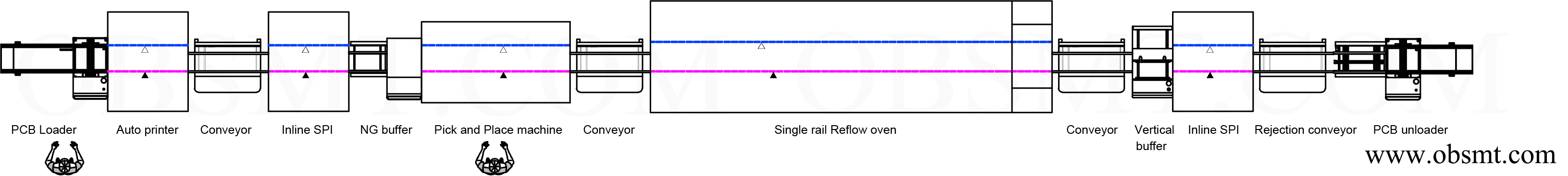

SMT Line Scheme:

Auto SMT Production Line(Single Rail)

1.PCB Loader (OB-L708)

2.Auto Printer (OB-CL400)

3.Conveyor (OB-C608)

4.Inline SPI

5.Pick and Place Machine (OB-M04)

6.Conveyor (OB-C608D)

7.Reflow oven (HS-0802-LF)

8.Conveyor (OB-C608C)

9.Vertical Buffer (OB-MBC608)

10.Inline SPI

11.Reject conveyor (OB-RC608)

12.PCB Unloader (OB-UL718)

OUBEL-Auto SMT production line

Any interested in our product,please contact hebe@obsmt.com