- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

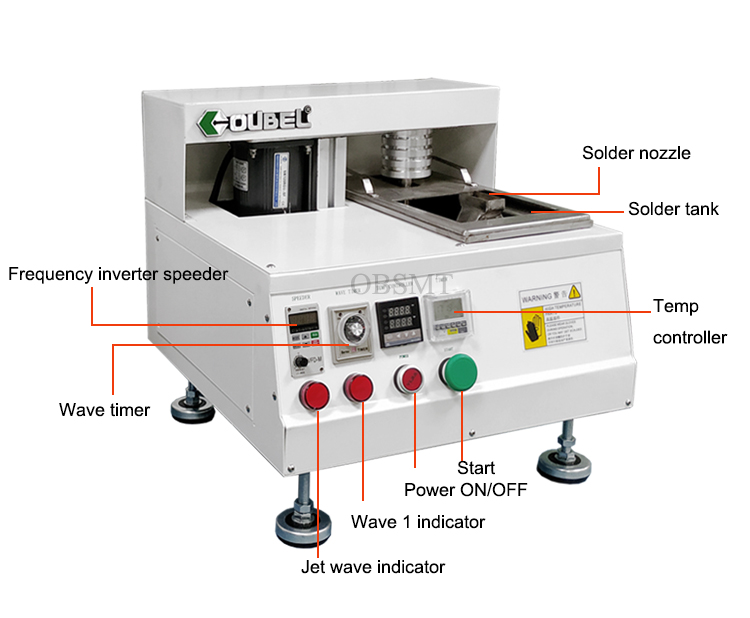

Jet wave soldering machine

Shop

Automatic microcomputer cutting machine

July 20, 2018

Automatic LED street assembly line

November 5, 2018Jet wave soldering machine

Model: OB-S310A

Brand: OUBEL

Delivery Time: 5 working days

Manual PCB jet wave soldering suitable for PCB welding or repair

Titanium solder tank + solder nozzle

Customized

Jet Wave Soldering Machine

Features

1. Applicable to special welding ; Mixed welding and other small-scale electronic manufacturers;Small batch production; experiment; teaching useful;

2. Do instrumentation, automotive, equipment manufacturers, PCB size, species complex, some special welding welding place ,Such as circuit patch plug mixed plate; automotive synthetic circuit board; LED lamp panel; Hardware Products Various local welding points less than the use of wave soldering and welding equipment welding place, you can use our desktopThe function of the local multi-point welding jet tin furnace welding operation;

3. Meet the circuit board and a variety of solder products use (with appropriate vents fixture);

4. Improve the welding quality, enhance efficiency;

5. The welding pin remains can be welded within 1-8 mm;

6. The tin furnace industrial furnace tube with lead-free materials, and probe temperature using a K-type thermocouple;

7. With the products with a variety of solder fixture, any purchase, also accept customized;

8. The temperature setting range up to 320 ° C;

9.Programmable the Switcher date, time, temperature, and other parameters;

10.Has short-circuit and over-current protection system design

WELDING:

Manual jet wave soldering pot is most suitable for the small batch PCBA DIP welding, especially for welding the parts of a PCBA ( SMD+DIP chips mixed).

REPAIR:

Manual jet wave soldering pot is most suitable for repair the PCBA,it can tear down the chips onto the PCBA.

Specifications

| Model | OB-S310A | |||||||

| Power | 2.6KW | |||||||

| Dimensions | 640*520*400mm | |||||||

| Material | Pure tiantium | |||||||

| Solder tank size | 330*160*100mm | |||||||

| Solder capacity | 23KGS | |||||||

| Nozzle size | 90*130mm | |||||||

| Power source | 1P 220V/50Hz-60Hz | |||||||

| Control method | By foot switch or by manual. Frequency converter stepless control. | |||||||

| Heating time | About 1H | |||||||

| Temp Precise | ±3° | |||||||

| Temp control method | PID+SSR | |||||||

| Start wave delay | 0-30s | |||||||

| Weight | Approx.40Kgs | |||||||

Leave message