- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Automatic selective wave soldering machine

Shop

IR curing oven

April 17, 2018

Manual flux sprayer

April 20, 2018Automatic selective wave soldering machine

Model: OB-SW400

Brand: OUBEL

Delivery Time: 30 working days

Automatic selective wave soldering machine

PLC+PC controller.

Automatic selective wave soldering machine

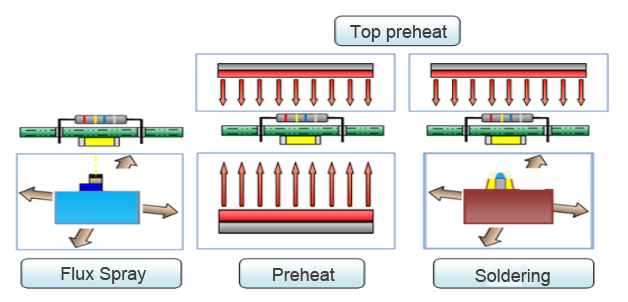

Operation process

1 step: PCB input by manual or smema contorl.

2 step: PCB high speed conveyed around to working point by sensor.

3 step: low speed to pneumatic stopper.

4 step: Vision inspection of position.

5 step: Board offset correction.

6 step: Flux nozzle sprays by programmed route.

7 step: Solder nozzle solder components by programmed route.

8 step: PCB released after soldering.

9 step: PCB conveyed out the equipment.

10 step: Waiting the PCB out signal or taken by manual.

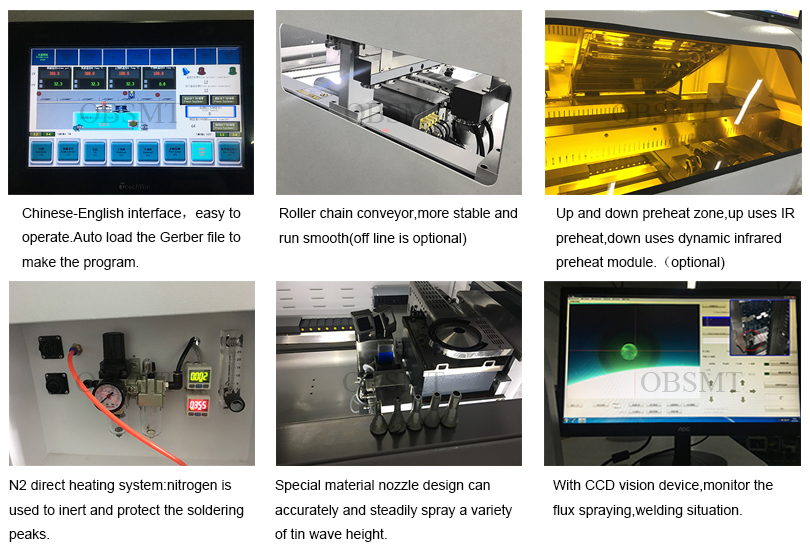

Features

1.Widely application range:used in solar energy,military equipment,aerospace,nuclear industry,automatic manufacturing and electronics enterprise.Fulfill the automatic production for factory!

2.Nozzle:Special material nozzle design can accurately and steadily spray a variety of tin wave height,thus improving the ability to continuously repeat welding in the case of space limited or too close to the part,by opening only for the welding point operation,no damage to other components.

3.N2 direct heating system:nitrogen is used to inert and protect the soldering peaks,while reducing the amount of tin slag.This unique nitrogen direct heat system uses the PID temperature control principle(0-400 degrees C)to heat wave peak.Let operators choose whether to increase or decrease the temperature.

4.Servo motor:the system uses th most accurate and advanced robot control technology-closed-loop servo,perfect repeatability of the intelligent motor.Ball screw anfd linear guide rail,accurate positioning,low noise,smooth movement.

Specifications

| Model | OB-SW400 |

| Outline dimension | (L) 1400*(W)1310*(H)1550mm |

| PCB size | 60*60mm-400*400mm |

| PCB thickness | 0.5-6.5mm |

| PCB weight | Max.9kg |

| Component height(upper side) | ≤130mm |

| Component height(bottom side) | ≤50mm |

| Solder pot capacity | 8kg |

| Temp.control accuracy | ±3℃ |

| No. of nozzle | 1 PC |

| Wheel type conveyor | Roller wheel |

| Conveyor height | 900+/-20mm |

| Conveyor direction | L-R or R-L |

| Spray method | Linear spray nozzle |

| Flux capacity/Spray pressure | 1-1.5L/0.5Mpa-0.1Mpa |

| Prheat temperature | Room temperature-150℃ |

| Temp.control accuracy | ±3℃ |

| Power source | AC220V1Φ50Hz or AC110V1Φ60Hz |

| Power consumption & source | 0.8KW/5KW |

| Equipment connection singal | SMEMA |

| Fluxer nozzle cleaning | Automatic |

| Net weight | Approx.600KG |

Leave message