- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

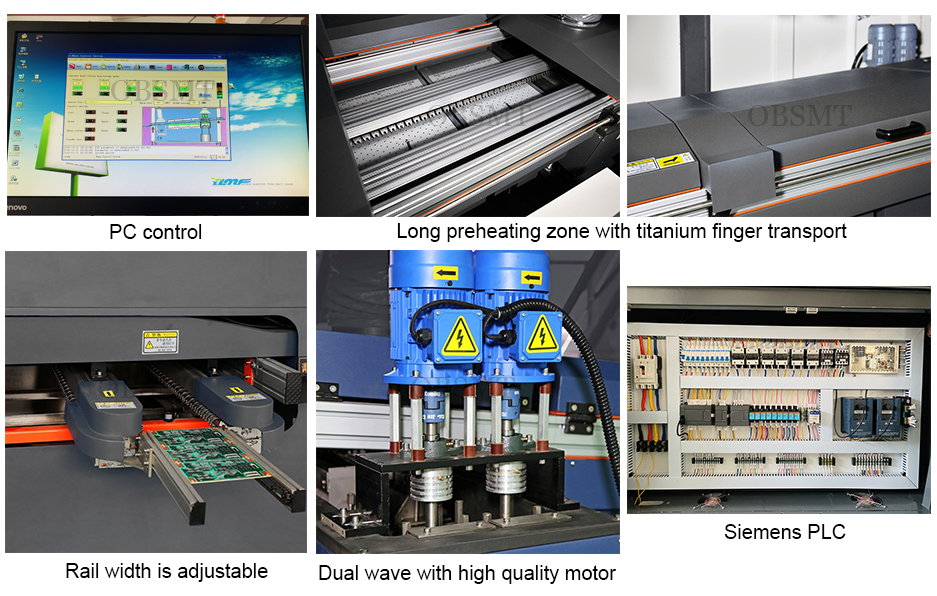

High-End Wave Soldering Machine SMART-450-E

Shop

PCB Loader With Conveyor

December 11, 2019

PCB NG OK Buffer Conveyor

March 26, 2020High-End Wave Soldering Machine SMART-450-E

Model: SMART-450-E

Brand: OUBEL

Delivery time: 15-20 working days

High-end wave soldering machine is used for welding PCB DIP chips.

High-End Wave Soldering Machine SMART-450-E

Features

1.Closed loop with inverter control system to keep the stability and accuracy of the conveyor speed;

2.The assistant pressure device nearby the entrance to prevent the PCB from slipping;

3.Spray nozzle driving by stepping motor is to make sure the coating uniformly;

4.Module design of spray fluxer system and the design of nozzle always be perpendicular to rail,which can make sure the flux penetrates PCB easily;

5. Forced air cooling system to attain the cold-down slope as per lead-free required;

6.Conveyor angle can easily be adjusted by manual;

7.Standard with hot air heating for preheating zones;

8.Module design suitable for SMT&THT component soldering;

9.Exhaust adopt centrifuagal fan with double filters to avoid any fluc drop to PCB;

10.The level of flux container is controlled by non-contact sensors to ensure no corrision and longer life;

11.Flux spray nozzle with self-cleaning system;

12.Stadard with air knives to prevent flux expand to preheat zone;

13.Wave height control adopted with inverter,it can be set individually;

14.1/4 HP high power mechanical pump to meet the wave as high as 15mm;

15.Light&Sound alarm,Emergency stop and over-load protection.

Specifications

| Model | SMART-450-E |

| Conveyor height | 750±20mm |

| Conveyor direction | L-R/R-L |

| Conveyor speed | 0-2.0m/min |

| PCB Working width | 0~450mm adjustable (standard) |

| Preheating zone length | 2000mm |

| Preheating zone quantity | 4 |

| Preheating temperature | Room temperature~250℃ |

| Wave quantity | Dual wave |

| Conveyor path gradient | 3~7° |

| Solder type | Lead free /lead tin |

| Solder volume | 430 kg |

| Solder temperature | Room temperature~350±1℃ |

| Component height | Top.120mm,Bottom.15mm |

| Temperature control type | P.I.D+SSR |

| Solder flux | 10~100ml/min |

| Controller | PLC+PC |

| Power | 3P 5 Wires (5W,3P) 380V |

| Power for heating up | 26kw |

| Power for operation | Approx.8kw |

| Air supply | 4-7kg/cm2 |

| Weight | Approx.2500kg |

| Dimensions L*W*H | 4600*1500*1750mm |

Leave message