- Welcome to OUBEL !

- +86 755 2954 6287

- sales@obsmt.com

Mini Wave Soldering Machine SE-200

Shop

Top Quality Wave Soldering Machine SMART-300-E

May 15, 2020

Professional Visual Inspection(AOI)

November 26, 2020Mini Wave Soldering Machine SE-200

Model: SE-200

Brand: OUBEL

Delivery Time: 10-15 working days

Description

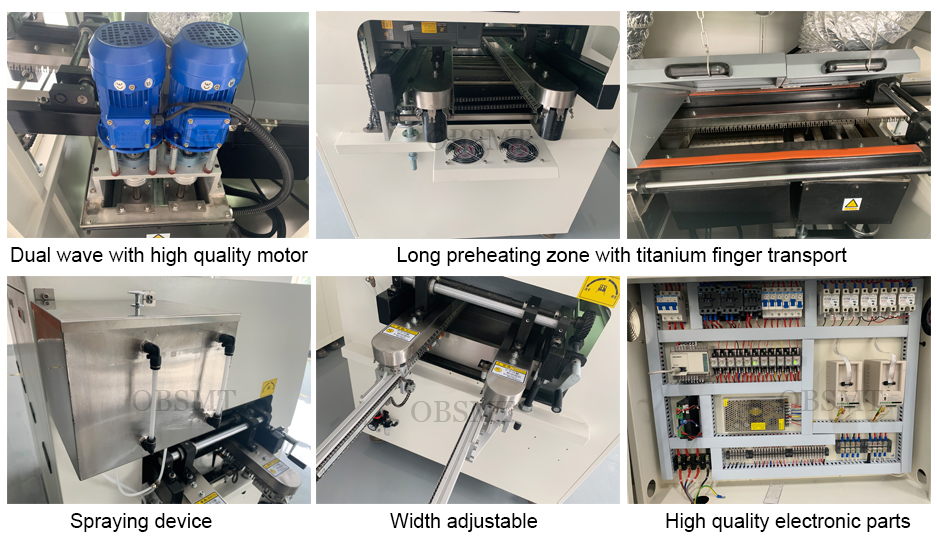

Mini Wave Soldering Machine SE-200

Dual wave.

Size can be customized.

Leave message

Description

Mini Wave Soldering Machine SE-200

Features

- Open canopy-style streamlined shell design, beautiful appearance, easy to clean;

- The lead-free solder furnace made of stainless steel production. High strength and hardness special aluminum rails, long lifespan;

- Applies to the PLC + touch screen controller, Ensure system reliability and stability;

- Spray system applies to the step motor , it can adjust the width according to the PCB size , save solder flux;

- Wave soldering stove adopt stepless electronic frequency control, it can independently control the wave height.

- The unique flux isolated device, flux fumes from the exhaust and recycling channel dedicated discharge, to meet environmental requirements.

- Programmable Automatic Turning the date, time, temperature and other parameters.

- equipped with a cooling module, the temperature compensation module, and a variety of process requirements for lead-freetechnique;

- The ceramic heating pipe preheating unit, fully stimulate the flux activity, to obtain good welding results. Radiation heat directly to the bottom of the PCB, heat, long life.

- Patented die-cast claw-type chain, titanium, non-stick tin, never deformation, long life, smooth and reliable transport PCB.

- The entire process transparent observation window for easy observation of the manufacturing and maintenance operations.

- Transportation system with stepless electronic speed control, PID control, transport speed and stability.

- Automatic start wave when go through the PCB, to minimize the amount of tin oxide.

- The temperature control system uses closed-loop PID control, temperature stable and reliable.

- With short circuit and overcurrent protection system.

Specifications

| Model | SE-200 |

| PCB conveyor height | Max.760±10mm |

| PCB conveyor direction | L-R |

| PCB conveyor speed | 0-2.0m/min |

| PCB Working width | 0~200mm adjustable (standard) |

| Preheating zone length | 400mm |

| Preheating zone number | 1 |

| Preheating temperature | Room temperature~250℃ |

| Wave | Dual wave |

| Conveyor path gradient | 3~7° |

| Solder type | Lead free /lead tin |

| Solder volume | 135kg |

| Solder temperature | Room temperature~350±1℃ |

| Solder tank size | 550*260*145mm |

| Temperature control type | P.I.D |

| Solder flux | 10~100ml/min |

| Refrigeration temperature | Below 10℃ |

| Sprayer Moving type | SMC cylinder |

| Power | 3P 5 Wires (5W,3P) 380V |

| Power for heating up | 8kw |

| Power for operation | Approx.2.5kw |

| Air supply | 3kg/cm2 |

| Weight | Approx.300kg |

| Dimensions L*W*H | 2200*1200*1600mm |

Leave message